Devilsown Stage 4 Kit

- Controls

1 or 2 Water Methanol Injection (WMI) pumps in forced

induction petrol or diesel setups

- Industry’s

first fully-configurable 3D map PWM duty control based on Engine RPM

and Boost - not available typical "progressive" controllers

- 4 General Purpose Outputs can be used for controlling boost control solenoids, anti-siphon solenoids, Fast Acting Valves, auxiliary high-impedance injectors, staged injection solenoids, lamps, relays, LEDs, or 3rd party Electronic Boost Controllers (EBCs)

- CANBus integration allows injection control based on parameters broadcast on the particular vehicle's internal CAN network

- Ideally

suited for Direct Injection or staged Water Methanol setups

- Advanced

built-in safety features not available on other rudimentary Water Methanol

Injection controllers

- Fully customisation operation

with easy to use TorqTune PC software

- TorqTune software also provides real-time data viewing, data

logging and data playback of all system parameters for unprecedented

ease of system tuning

The stage 4 controller is the most

advanced programmable water methanol pump controller on the market. It is capable

of simultaneously driving two individually-controllable water methanol

injection (WMI) pumps and four individually controllable anti-siphon solenoids, Fast Acting W/M injection valves, auxiliary high impedance

injectors or any combination thereof. It has two pump outputs

is capable of supplying up to 15A to the connected pump.

Stage 4 Controller Strategy:

Standard progressive controllers can only drive a single delivery pump. They also usually have only a single channel for driving an optional anti-siphon on/off solenoid valve. This makes them somewhat less than optimal for use in direct injection set-ups or staged set-ups that require a lot of stages.

The higher-end European controllers can only drive a single delivery pump and one

“fast response valve”. They cannot be configured for multiple stages of

delivery, but they are provided with optional direct injection manifolds for 4,

6 and 8 cylinder configurations.

Our stage 4 controller can drive two delivery pumps and four on/off solenoids

or “fast response valves” or two of each solenoid type. The users can

implement a VPD control approach based on RPM, boost or another 0-5V signal of

their choice. They can also implement the FPD-VSD control strategy that is

based on RPM, boost or another 0-5V signal. Because the Controller has two PWM

pump outputs and two General Purpose outputs (GPOs) which can either drive

On/Off solenoids or PWM “fast response valves”, the user can implement a hybrid

VPD/FPD-VSD control strategy or something completely new and unique.

One Stage - Intake mounted nozzle

One Stage - Direct Injection / Manifold mounted nozzle with anti-siphon solenoid

Two Stage - Intake mounted nozzles

Two Stage - Direct Injection / Manifold mounted nozzles

with anti-siphon solenoids

Three Stage - Intake mounted nozzles

Three Stage - Direct Injection / Manifold mounted nozzles with

anti-siphon solenoids

Four Stage - Intake mounted nozzles

TorqTune Software

In spite of its sophistication, the software is extremely easy to

install and configure with our intuitive TorqTune PC software.

This free software allows users to fully configure the operation of the Controller.

Certain parameters, such as duty cycle maps, can be adjusted with the engine

running for real-time tuning. Additionally, TorqTune allows the user to live

view many of the unit’s internal parameters, log them to a file and save them

for later playback or for sharing with others. These advanced functions allow

the user to observe the effects of various configuration changes in order

to achieve unprecedented control of their methanol injection and/or fuel

pump operation.

TorqTune software can store your Controllers configuration settings

in special TTINI files that you can store on your hard drive or share with

other users. Other users' configuration files can be loaded into

your Controller and used "as-is" provided your set-up is the same as

the other user's or they can be used as a starting point for

your own customization. TorqTune software can also log and play back

saved log files which can be analysed in TorqTune or in Excel.

These features make the Controller and TorqTune ideal for tuners who

need to work on their customers' vehicles remotely.

The feature set provided by our controller and its accompanying TorqTune software is not available with any other water methanol injection or fuel control system.

A Controller that Evolves with your Setup

If you don't need all of the Controllers advanced functionality right

away, you can use TorqTune to configure the Controller to operate as a

dumb "progressive" controller equipped with two adjustment

trim-pots for manually setting the pump activation boost point

and the "full pump speed" boost point.

The controller is designed to be future-proof. Its internal

unit firmware can be upgraded from your PC so you can continue

to take advantage of new features and enhancements as they are

rolled out. Simply download the latest firmware from our website and

reflash your Controller from the TorqTune software. As always, all firmware and

software updates are free for all our customers and our dealers.

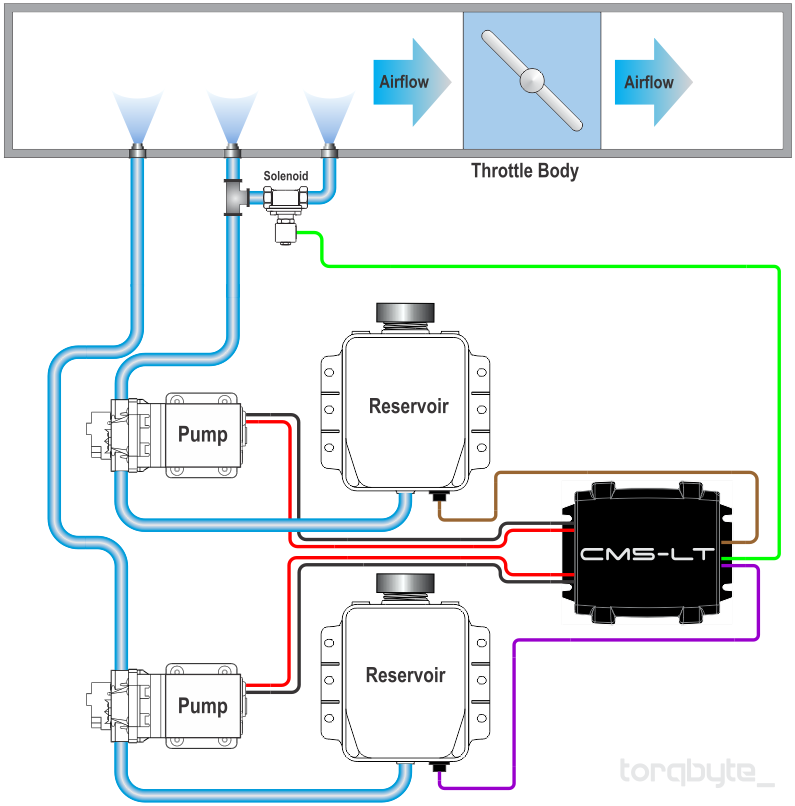

Block wiring diagram is shown below:

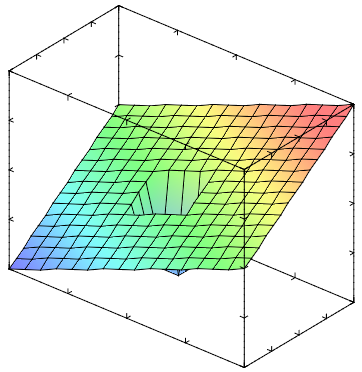

Industry’s First TRUE 3D WMI Pump Duty Mapping

The Controllers water methanol injection delivery is fully digital

and is completely customizable by the user through a 16x16 table (i.e. a

256 point map) which is downloaded into the unit.

Other water methanol kit providers state that their pump

controllers are "digital", but what do they really mean by that.

Sure, some of them come with a basic "digital" display that

shows parameters like boost or pump duty, but how truly

"digital" is their internal operation? As a

true digital controller, the Controller is built around a

fast microprocessor that performs 2-dimensional linear interpolation simultaneously

in both vertical (boost or voltage) and horizontal (RPM) axes to

generate pump duty values which change smoothly and

gradually between all adjacent table cells. This is the same algorithm

used in today's modern Engine Control Units (ECUs).

Need extra water meth at a certain RPM & boost point, in

an otherwise linear map? No problem

Need to add a small dip in water meth

delivery required at another RPM & boost point? No

problem.

The other controllers simply don't provide this level of flexibility,

especially not in one unit that can control four outputs each with its own

unique configuration table.

The controller is supplied with a 4-Bar MAP sensor, but the TorqTune

software allows you to configure the unit to use any 0-5V MAP or gauge pressure

sensor of your choice. This is an important if you are using the controller on

something like a high-performance diesel set-up that sees up to

or over 100PSI of boost.

If you do not want to base your water methanol injection on RPM

and boost, you don’t have to. Pump duty can be based on just RPM or just

boost. Don't want to base the Water Methanol Injection control on boost

pressure? Want to use some other 0-5V sensor or signal? No Problem. Select what

you want to use for the vertical axis source

If other exotic or unorthodox water methanol control schemes

are required, the Controllers two spare 0-5V analogue inputs can

replace boost as the vertical axis in each of the

tables so you can base the pump duty on another 0-5V

signal, such as the MAF or the TPS. You could even base your water

methanol delivery on the 0-5V output of an O2 sensor controller or even a

simple manual pot. You are in full control of your WMI pump

operation at all times allowing you to make it fit virtually any

vehicle or engine set-up.

The Controller always stores the user-loaded 3D duty maps in its

on-board, non-volatile memory. TorqTune software can store these maps in

calibration files and allow them to be saved, opened, edited and shared.

Pump duty cycle, boost, RPM and a number of other parameters can be logged and

played back using the TorqTune software. Users can easily edit and customize

the water methanol delivery calibrations for their specific engine

configuration.

Low Power Outputs

Besides the two high power pump outputs, The controller also provides you with four low power General Purpose Outputs (GPOs) whose operation is also fully customizable through their own dedicated 256 point map tables that can vary the duty of each GPO based on engine RPM plus another 0-5V parameter such as boost pressure or a spare analogue voltage.

The low power GPOs are pull-to-ground type outputs and are capable continuously sinking up to 1A from each attached load. A typical use for the GPOs is controlling staged injection solenoids or an anti-siphon fluid control solenoid which prevents methanol water mixture siphoning in set-ups where the water methanol pump is mounted below the water methanol tank or where the water methanol nozzles are mounted behind the throttle plate and can leak while exposed to engine vacuum. This same solenoid can also be used to restrict fluid flow momentarily before injection allowing the water methanol pump to build line pressure and ensure better atomization of the water methanol mixture when the solenoid opens.Another popular use for the GPOs is controlling an additional high-impedance injector. This additional injector can provide additional fuel when the user's set-up has outgrown the capabilities of the stock injectors. In addition to improving the overall fuel delivery, the additional injector can sometimes help alleviate the problems typically seen in direct injection systems, such as carbon build up.

Other uses for these outputs are activation (or deactivation) of loads

such as relays, lamps or LEDs that can be used to control other systems in the

vehicle or provide visual indication to the driver based on the 256 point table

configuration.

Spare Analog Inputs

The controller comes with two spare 0-5V analogue inputs. Either of these spare

inputs can be used to control any of the four 256 point tables instead of

the default MAP sensor.

Whether the two spare analogue inputs are used instead of the MAP

sensor to control the duty of one of the outputs or not, both can

still be used for live-viewing and/or data logging allowing the user to record

and analyse parameters including, intake or exhaust temperature, throttle

position (TPS), Mass Air Flow (MAF) reading, water methanol Flow Sensor output

or Air/Fuel Ratio (AFR) taken from a Wideband O2 sensor controller.

Spare Logic Inputs

The controller provides the user with two active-low logic inputs. An open

circuit on these two inputs is considered inactive. However, connecting either

of these inputs to ground, through a switch or a relay, signals an active state

to the controller and allows it to take a pre-defined action.

For example, if the user has configured the Controller for boost control, these

inputs can be used to select between two boost set-points or put the car in

valet mode where the boost is set to the lowest possible (i.e. wastegate

spring) boost level. Many other uses are certainly possible and are only limited by the

user’s configuration.

Built-In Safety Features

Our stage 4 controller actively monitors the current passing through its

dual high power pump outputs. The user is able to set the unit’s undercurrent

and overcurrent limits using TorqTune software to guard against problems that

could be caused by electrical malfunctions or component defects in their fuel

or water methanol injection system. For example, if excess current draw is

detected that exceeds the user-entered overcurrent limit; it could be an

indication of a short circuit in the pump or in the wiring or a blocked line

which is causing the pump to overload. On the other hand, if the current draw

drops below the user-entered undercurrent limit; it could be an indication of a

break in the wiring, an empty tank, or a faulty pump. The Controller can detect

and flag these faults to the user or can take action like reducing boost to its

lowest setting to protect the engine (only in configurations where the Controller

is controlling the boost solenoid). This is a feature not available on any

other controller.

Optional Displays

In most cases users will use a laptop or a tablet with a USB connection to communicate with the Controller and view, log and modify its various measurements and parameters. For users wishing to view just some of the parameters, The controller provides a low-speed serial communications port for displaying the following:

- Actual Boost

- Target Boost (if used)

- Auxiliary Input Value (if

used)

- Battery Voltage

- Boost Solenoid Duty (if

used)

- Main Output Duty

- Auxiliary Output Duty

- Engine RPM

Users can purchase

separately DM1 display module or Bluetooth module, users can download

the free TorqView software which allows them to view

all important unit parameters on a small 7"-9" Windows tablet that

can be mounted on the dash.

Kit Contents

- Stage 4 controller

- 4 Bar map sensor

- Controller wiring loom

- 300psi pump with EPDM seals

- Allen key can be used to

adjust water pump pressure

- 15' of High Pressure Black

Tubing

- Injector (please supply

engine cc & max boost + rpm so we can supply appropriate sizes).

- Nozzle Holder

- Check valve

- Stage 4 controller

Stage 4 Kit

- Product Code:stage4

- Availability:In Stock

-

£637.49

Available Options

Related Products

8 Cyl Stainless steel Direct port (RACE)

Direct port distributes spray evenly. However, putting mist at the backs of those intake valves ON T..

£916.65

6 Cyl Direct port (RACE)

Direct port distributes spray evenly. However, putting mist at the backs of those intake valves ON T..

£562.46

Stage 4 Torqbyte CM5-LTS controller

CM5-LTS - Water Methanol Injection ControllerControls 1 or 2 Water Methanol Injection (WMI) pum..

£399.99

BMW Stealth Tank M3 M4 F30 F32

The 3 gallon stealth tank the WMI pump mounts directly to the tank and the entire assembly fits..

£266.63

TORQBYTE VAG PM4 HIGH POWER FUEL PUMP CONTROL MODULE FWD MQB

VAG PM4 High Power FPCM Complete Plug-n-Play replacement for the factory Fuel Pump Control Modu..

£607.49 £674.99

BMW F10 M5 Stealth tank

This completely custom design fits cleanly within the existing trunk cavity in your F10 BM..

£266.63

BMW 3.5 Gallon Stealth Tank for G20 G22 & G80 M3 & G82 M4 BMW

Stealth Tank for G20 G22 & G80 M3 & G82 M4 BMW tucks neatly in the side pocket of&..

£308.33